Introduction

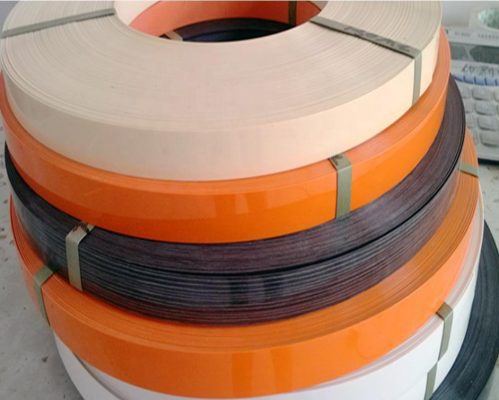

ABS (Acrylonitrile Butadiene Styrene) edging is commonly used in furniture and cabinetry for its durability and ability to provide a clean, finished look. To achieve a strong and lasting bond when applying ABS edging, it is essential to use the right adhesive. In this article, we will explore the best types of glue for ABS edging and provide tips for achieving optimal results.

Best Types of Glue for ABS Edging

- Contact Cement

- Description: Contact cement is a widely used adhesive for bonding ABS edging due to its strong initial tack and excellent bonding properties.

- Advantages:

- Strong and durable bond

- Fast-drying

- Easy to apply

- Application: Apply contact cement to both the ABS edging and the substrate. Allow it to become tacky, then press the edging firmly onto the substrate.

- Hot Melt Adhesive

- Description: Hot melt adhesive is another popular choice for ABS edging, especially in industrial applications. It provides a quick and strong bond.

- Advantages:

- Fast setting

- Strong bond

- Suitable for automated processes

- Application: Use a hot melt glue gun to apply the adhesive to the edging or substrate. Quickly press the edging into place before the glue cools.

- Polyurethane (PU) Adhesive

- Description: Polyurethane adhesive is known for its strong bond and versatility. It works well with a variety of materials, including ABS.

- Advantages:

- Strong, flexible bond

- Moisture-resistant

- Suitable for various surfaces

- Application: Apply the adhesive to the substrate, then position the ABS edging. Clamp or hold in place until the adhesive sets.

- Epoxy Resin

- Description: Epoxy resin provides a high-strength bond and is suitable for demanding applications where durability is crucial.

- Advantages:

- Extremely strong bond

- Resistant to chemicals and heat

- Long-lasting

- Application: Mix the two components of the epoxy, apply to the substrate, and press the ABS edging into place. Allow sufficient curing time as specified by the manufacturer.

- Cyanoacrylate (Super Glue)

- Description: Super glue is a quick-bonding adhesive that works well for small or intricate areas where precise application is needed.

- Advantages:

- Instant bonding

- Easy to apply

- Suitable for small repairs

- Application: Apply a small amount of glue to the substrate and press the ABS edging into place. Hold until the bond is secure.

Tips for Best Results

- Surface Preparation: Ensure that the surfaces to be bonded are clean, dry, and free of dust, oil, or other contaminants. Use isopropyl alcohol or a similar cleaner to prepare the surfaces.

- Apply Even Pressure: Apply consistent pressure along the entire length of the edging to ensure a uniform bond. Use clamps or a roller for larger pieces.

- Follow Manufacturer’s Instructions: Always follow the adhesive manufacturer’s instructions for application, drying times, and safety precautions.

- Test on Scrap Pieces: If you are unsure about the compatibility of the adhesive with your materials, test it on a scrap piece first.

Conclusion

The best glue for ABS edging depends on your specific project requirements and the desired bond strength. Contact cement, hot melt adhesive, polyurethane adhesive, epoxy resin, and cyanoacrylate are all excellent choices, each with its own advantages. By preparing the surfaces properly and following best practices for application, you can achieve a strong and durable bond that enhances the appearance and longevity of your ABS-edged projects.