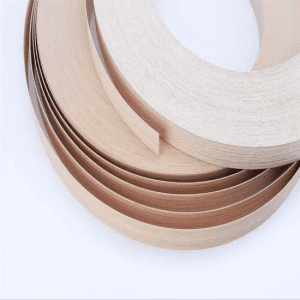

ABS (Acrylonitrile Butadiene Styrene) edge banding

ABS (Acrylonitrile Butadiene Styrene) edge banding is a popular choice for finishing and protecting the exposed edges of various materials, such as plywood, MDF, and particleboard. It comes with its own set of advantages and disadvantages:

Advantages of ABS Edge Banding:

- Durability: ABS edge banding is known for its durability and resistance to impact, abrasion, and wear. It provides long-lasting protection to the edges of materials.

- Moisture Resistance: ABS is moisture-resistant, making it suitable for applications in kitchens, bathrooms, and other environments where exposure to moisture is a concern.

- Consistency: ABS edge banding offers a consistent appearance and texture throughout the roll or length of the material, ensuring a uniform look when applied to multiple edges.

- Wide Range of Colors and Textures: ABS edge banding is available in a variety of colors, patterns, and textures, allowing you to match or contrast with the material you’re covering.

- Ease of Maintenance: ABS edge banding is easy to clean and maintain, making it suitable for surfaces that may encounter spills, dirt, or other contaminants.

- Versatile Application: It can be applied to straight edges, curves, and corners, making it versatile for a range of woodworking and cabinetry projects.

ABS edge banding

ABS edge banding

ABS edge banding

ABS edge banding

ABS edge banding

ABS edge banding

We are an ABS edge banding manufacturer from China, Elevate your woodworking projects to new levels of precision and durability with our top-notch ABS Edge Banding. Crafted to seamlessly meld with your designs, our ABS edge banding offers a flawless finish that not only enhances aesthetics but also protects against wear and tear. Whether you're working on cabinets, shelves, or furniture, our ABS edge banding delivers exceptional impact resistance and moisture protection. With a diverse range of colors and sizes, you'll find the perfect match to bring your vision to life. Trust in the quality of ABS edge banding that ensures your creations withstand the test of time.