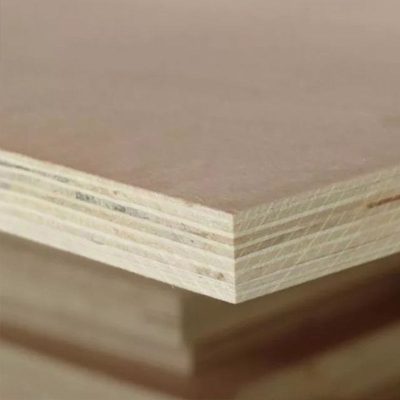

Yes, edge banding is commonly used on plywood and other engineered wood products to provide a finished and polished appearance to the exposed edges. Plywood edges are typically rough and have visible layers, so applying edge banding helps conceal these imperfections and provides a clean, professional look.

Here are the general steps for applying edge banding to plywood:

Materials and Tools Needed:

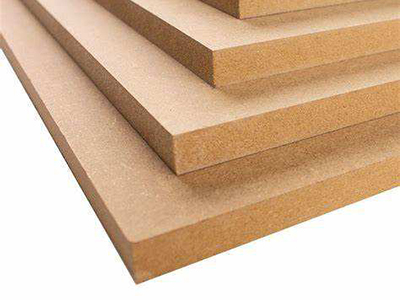

- Plywood panel with exposed edges

- Edge banding material (PVC, ABS, wood veneer, etc.)

- Edge banding trimmer or utility knife

- Iron or hot air gun (for heat-activated adhesives)

- Roller (for even application and adhesion)

- Sandpaper (optional, for smoothing edges before applying)

Plywood edge sealing steps:

- Prepare the Plywood:

- Ensure that the exposed edges of the plywood are clean, smooth, and free from dust or debris. If needed, sand the edges to create a smooth surface for better adhesion.

- Cut the Edge Banding:

- Cut the edge banding material to the length of the plywood edge. It’s a good practice to cut the edge banding slightly longer than the edge to allow for trimming later.

- Apply Heat (if using heat-activated adhesive):

- If the edge banding has a heat-activated adhesive (common with PVC or wood veneer edge banding), use an iron or hot air gun to apply heat to the adhesive side. This softens the adhesive and ensures a secure bond.

- Apply the Edge Banding:

- Press the edge banding onto the plywood edge, aligning it carefully to cover the exposed edge completely. Use a roller to apply even pressure, ensuring good adhesion.

- Trim Excess:

- Once the edge banding is applied, trim the excess material using an edge banding trimmer or a sharp utility knife. Trim along the edges, following the contour of the plywood.

- Smooth Edges (if needed):

- After trimming, you can use sandpaper to smooth the edges further if desired. This helps create a seamless transition between the edge banding and the plywood surface.

- Finish and Seal (optional):

- Depending on the type of edge banding material used, you may choose to finish or seal the edges for additional protection or to match the overall finish of the project.

- Depending on the type of edge banding material used, you may choose to finish or seal the edges for additional protection or to match the overall finish of the project.

Using edge banding on plywood is a common practice in cabinetmaking, furniture construction, and other woodworking projects. It enhances the appearance of the finished product and provides a durable and professional edge finish.