There are several types of edge banding used in woodworking and furniture manufacturing, but three common types are:

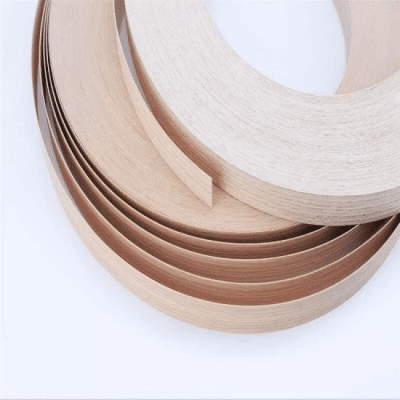

- Wood Veneer Edge Banding:

- Material: Real wood veneer.

- Description: Wood veneer edge banding is made from thin slices of real wood, typically around 0.6mm to 2mm in thickness. The wood veneer is often applied to a paper or fleece backing for flexibility.

- Usage: Popular for applications where a genuine wood appearance is desired. It allows for the use of less expensive substrates like MDF or particleboard while maintaining a real wood look on the edges.

- PVC (Polyvinyl Chloride) Edge Banding:

- Material: Synthetic plastic (PVC).

- Description: PVC edge banding is made from a plastic material (PVC) that is extruded into thin strips. It is available in various colors, patterns, and finishes.

- Usage: Commonly used for a cost-effective and durable solution. It is often applied to furniture made from engineered wood products like particleboard or MDF.

- ABS (Acrylonitrile Butadiene Styrene) Edge Banding:

- Material: Thermoplastic polymer (ABS).

- Description: ABS edge banding is made from a thermoplastic polymer known as ABS. It is similar to PVC edge banding but is considered to be more environmentally friendly.

- Usage: Used in various applications where a durable and impact-resistant edge is required. ABS is known for its toughness and resistance to impact.

Each type of edge banding has its own set of characteristics, advantages, and applications. The choice of edge banding depends on factors such as the desired appearance, budget, durability requirements, and the specific application or project. It’s common for manufacturers to use a combination of these edge banding types based on the project’s design and functional needs.