When adhering melamine to wood, it’s essential to choose the right adhesive to ensure a strong and durable bond. The best adhesive for bonding melamine to wood depends on the specific requirements of your project and the type of wood you are working with. Here are some adhesive options to consider:

- Contact Cement: Contact cement is a popular choice for bonding melamine to wood. It is applied to both surfaces, allowed to dry until tacky, and then pressed together. Contact cement forms a strong bond and is suitable for laminating melamine to plywood, MDF, or particleboard.

- PVA (Polyvinyl Acetate) Glue: PVA glue, commonly known as wood glue, can also be used to bond melamine to wood. It is particularly effective when working with solid wood edges or applying edge banding. Ensure that the wood surfaces are clean and properly prepared before applying PVA glue.

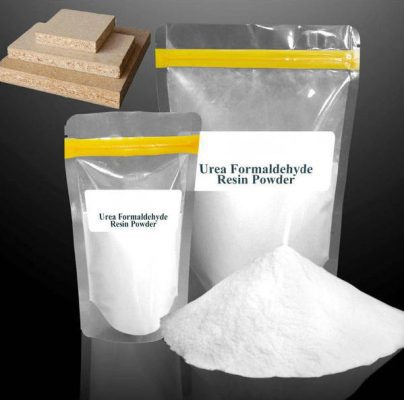

- Urea Formaldehyde (UF) Glue: UF glue is a strong adhesive commonly used in the woodworking industry. It can be used to bond melamine to wood, but it typically requires special equipment for application, such as a hot press. UF glue forms a very strong and durable bond.

- Hot Melt Adhesive: Hot melt adhesives, such as EVA (Ethylene Vinyl Acetate) or PUR (Polyurethane Reactive) hot melt, can also be used for bonding melamine to wood. These adhesives are heated and applied using a hot melt adhesive system. PUR hot melt, in particular, offers excellent moisture resistance and durability.

5.Spray Adhesive: Spray adhesives are available in aerosol cans and can be used for bonding melamine to wood when a uniform and thin adhesive layer is required. These adhesives are convenient for applying to large surfaces and can provide a strong bond.

6.Double-Sided Tape: Double-sided adhesive tapes with a high bond strength can be used for bonding melamine to wood in applications where a permanent bond is not necessary. They are quick and easy to apply.

When selecting an adhesive, consider factors such as the type of wood, the environmental conditions the bond will be exposed to (e.g., humidity), and the application method. Always follow the manufacturer’s instructions for the chosen adhesive, including surface preparation and curing times, to ensure the best results. Additionally, proper clamping or pressure may be required to achieve a strong bond, especially when using contact cement or PVA glue.