Introduction

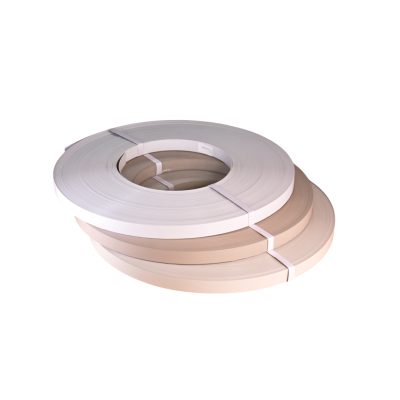

Edge banding is an essential component in cabinetry and furniture making, providing a finished look to raw edges and protecting them from damage. With various types of edge banding available, choosing the most durable option can be challenging. In this article, we’ll explore different edge banding materials and determine which is the most durable, helping you make an informed decision for your projects.

1. PVC (Polyvinyl Chloride) Edge Banding

PVC edge banding is one of the most commonly used materials due to its durability and versatility. It is resistant to moisture, heat, and impact, making it suitable for high-traffic areas and environments with fluctuating temperatures.

Advantages:

- High durability and resistance to wear

- Moisture and heat resistant

- Available in various colors and finishes

Applications:

- Kitchen and bathroom cabinets

- Office furniture

- High-use residential furniture

2. ABS (Acrylonitrile Butadiene Styrene) Edge Banding

ABS edge banding is an eco-friendly alternative to PVC. It offers similar durability and resistance to impact and heat but is made from recyclable materials, making it a greener option.

Advantages:

- Durable and impact resistant

- Heat and chemical resistant

- Environmentally friendly

Applications:

- Children’s furniture

- Office and commercial furniture

- Residential furniture

3. Wood Veneer Edge Banding

Wood veneer edge banding provides a natural look and feel, as it is made from thin slices of real wood. While it offers aesthetic appeal, it is not as durable as synthetic materials in terms of moisture and impact resistance.

Advantages:

- Natural and authentic appearance

- Can be stained or finished to match the surface

- Eco-friendly

Applications:

- High-end furniture

- Custom cabinetry

- Decorative pieces

4. Metal Edge Banding

Metal edge banding, typically made from aluminum or stainless steel, offers exceptional durability and a modern aesthetic. It is highly resistant to impact, heat, and moisture, making it ideal for heavy-duty applications.

Advantages:

- Extremely durable and long-lasting

- Resistant to heat, moisture, and impact

- Modern and sleek appearance

Applications:

- Commercial and industrial furniture

- High-traffic areas

- Contemporary furniture designs

5. Melamine Edge Banding

Melamine edge banding is made from paper saturated with resin, providing a cost-effective and durable option. It is available in a wide range of colors and patterns, mimicking wood, stone, and other materials.

Advantages:

- Affordable and versatile

- Resistant to scratches and moisture

- Easy to apply

Applications:

- Budget-friendly furniture

- Office furniture

- Residential cabinetry

Conclusion on the most durable edge banding

When it comes to durability, PVC edge banding stands out as one of the most robust options due to its resistance to moisture, heat, and impact. However, ABS edge banding offers similar durability with the added benefit of being environmentally friendly. For those seeking an extremely durable and modern option, metal edge banding provides superior strength and longevity.

Ultimately, the choice of edge banding depends on the specific requirements of your project, including the desired appearance, environmental considerations, and the level of wear and tear the furniture will endure. By understanding the strengths and applications of each type of edge banding, you can select the most suitable and durable option for your needs.