Acrylic edge banding is a popular choice for adding a sleek, modern finish to furniture and cabinetry projects. It provides a durable and attractive edge treatment that complements various design styles. In this comprehensive guide, we’ll cover everything you need to know about acrylic edge banding, including its features, advantages, installation methods, and maintenance tips.

1. Features of Acrylic Edge Banding:

- Material Composition: Acrylic edge banding is made from acrylic resin, which is a thermoplastic polymer known for its transparency, durability, and impact resistance.

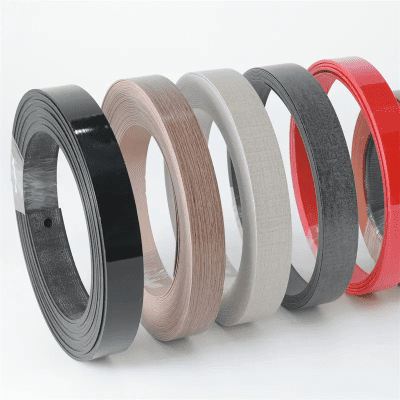

- Appearance: Acrylic edge banding offers a high-gloss, glass-like appearance that enhances the overall aesthetics of furniture and cabinetry. It provides a seamless and modern finish to edges.

- Color Options: Acrylic edge banding is available in a wide range of colors, including solid colors, metallics, and transparent finishes. This variety allows for customization and coordination with different surface materials.

- Thickness: Acrylic edge banding is typically available in thicknesses ranging from 0.5mm to 3mm, offering flexibility in achieving different edge profiles and designs.

2. Advantages of Acrylic Edge Banding:

- High Aesthetic Appeal: Acrylic edge banding provides a sleek and contemporary look, making it a popular choice for modern furniture and cabinetry designs.

- Durable and Scratch-Resistant: Acrylic edge banding is highly durable and resistant to scratches, abrasions, and impact, ensuring long-lasting performance.

- Moisture Resistance: Acrylic edge banding is non-porous and resistant to moisture, making it suitable for use in kitchens, bathrooms, and other humid environments.

- Easy to Clean: Acrylic edge banding can be easily cleaned with mild soap and water, maintaining its glossy finish over time.

- Versatility: Acrylic edge banding is compatible with various substrates, including plywood, MDF, particleboard, and solid wood, offering versatility in furniture and cabinetry applications.

3. Installation Methods for Acrylic Edge Banding:

- Hot Air or Hot Melt Application: Acrylic edge banding is typically applied using a hot air or hot melt edge banding machine. The heat activates the adhesive backing on the edge banding, allowing it to bond securely to the edge of the substrate.

- Manual Application: Acrylic edge banding can also be applied manually using a household iron or edge banding trimmer. The edge banding is heated with the iron, and pressure is applied to ensure proper adhesion.

4. Maintenance Tips for Acrylic Edge Banding:

- Regular Cleaning: Clean acrylic edge banding regularly with a soft cloth and mild soap and water to remove dust, dirt, and fingerprints.

- Avoid Harsh Chemicals: Avoid using abrasive cleaners or harsh chemicals that may damage the surface of the acrylic edge banding.

- Prevent Scratches: Use felt pads or coasters under objects to prevent scratches and abrasions on the surface of the acrylic edge banding.

- Repair Minor Damage: Minor scratches or scuffs on acrylic edge banding can often be repaired using a plastic polish or scratch remover.

Conclusion:

Acrylic edge banding offers a combination of aesthetic appeal, durability, and versatility, making it an ideal choice for enhancing the edges of furniture and cabinetry projects. By understanding its features, advantages, installation methods, and maintenance tips, you can achieve professional results and create stunning finished products with acrylic edge banding.