What Type of Edge Banding Glue Should You Use? Edge banding glue is an essential component in the furniture manufacturing process. It secures the edge banding material to the substrate, ensuring a polished and durable finish. Choosing the right type of glue can make a significant difference in the quality and longevity of the final […]

Category Archives: Edge Banding Glue Article Topic

Edge Banding Glue Article Topic

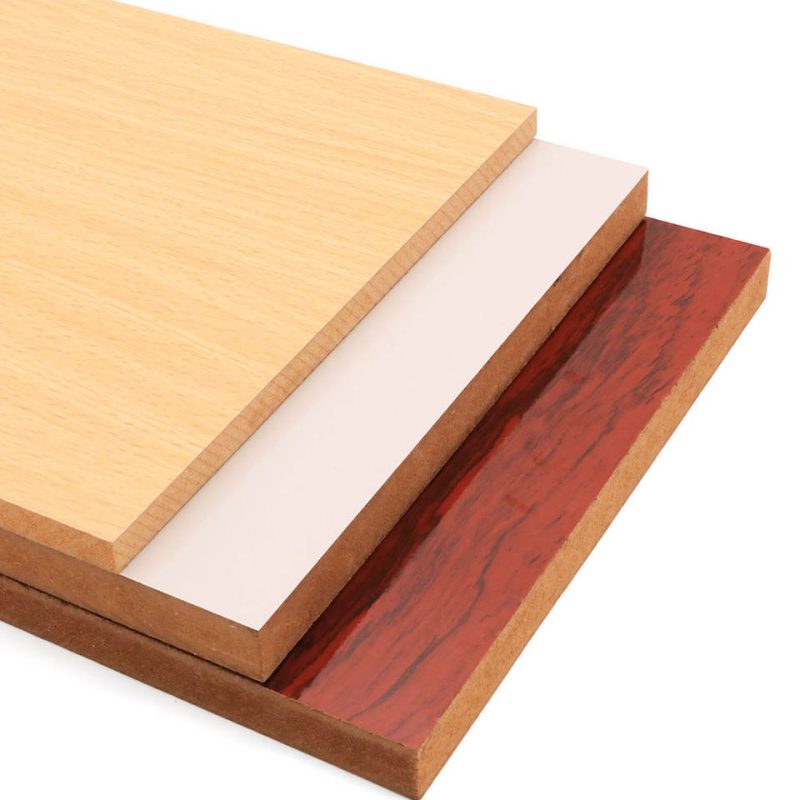

Introduction Edge banding is an essential component in cabinetry and furniture making, providing a finished look to raw edges and protecting them from damage. With various types of edge banding available, choosing the most durable option can be challenging. In this article, we’ll explore different edge banding materials and determine which is the most durable, […]

When it comes to kitchen renovations, one often overlooked but crucial element is the edging of kitchen worktops. Properly securing the edging ensures not only a polished look but also long-lasting durability. Choosing the best glue for kitchen worktop edging is essential for achieving professional results. In this guide, we’ll explore the top adhesives, their […]

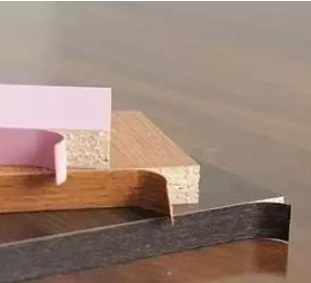

Yes, edge banding can be used on MDF (Medium-Density Fiberboard). Edge banding is a common and effective way to finish and protect the exposed edges of MDF, just as it is used on other engineered wood products like plywood and particleboard. Here are the steps to apply edge banding to MDF: Materials You’ll Need: Edge […]

When adhering melamine to wood, it’s essential to choose the right adhesive to ensure a strong and durable bond. The best adhesive for bonding melamine to wood depends on the specific requirements of your project and the type of wood you are working with. Here are some adhesive options to consider: Contact Cement: Contact cement […]

Several types of adhesives are considered stronger than hot glue, depending on the specific application and materials involved. Hot glue, or hot melt adhesive, has its advantages, such as quick setting and versatility, but it may not always provide the strongest bond. Here are some adhesives that are generally stronger than hot glue: Epoxy Resin: […]

EVA (Ethylene Vinyl Acetate) and PUR (Polyurethane Reactive) are two different types of adhesives used in the production of edgebanding, which is applied to the edges of panels, such as those used in furniture manufacturing. Here are the key differences between EVA and PUR edgebanding glue: EVA (Ethylene Vinyl Acetate) Edgebanding Glue: Application: EVA glue […]

EVA (Ethylene Vinyl Acetate) hot melt adhesive, commonly used in woodworking and edge banding applications, typically melts and flows at a temperature range of approximately 150°C to 180°C (302°F to 356°F). This temperature range allows EVA hot melt adhesive to become molten and ready for application. When using EVA hot melt adhesive, it’s important to […]

The temperature at which you should glue edge banding depends on the type of adhesive you are using. The most common adhesive for edge banding is hot melt adhesive (hot glue), and it is typically applied within a specific temperature range. Here are general temperature guidelines for gluing edge banding with hot melt adhesive: Temperature […]

The choice of adhesive for PVC edge banding is critical to achieving a strong and long-lasting bond. The “best” adhesive can vary depending on factors such as the application method, environmental conditions, and personal preferences. However, there are several types of adhesives commonly used for bonding PVC edge banding to substrates like plywood, MDF, or […]

- 1

- 2