Pre-glued edge banding refers to a type of edge banding material that comes with adhesive already applied to one side. This adhesive is activated by heat, typically using an iron or an edge banding machine, facilitating the bonding process during application. The pre-glued edge banding eliminates the need for a separate adhesive application step, making […]

Category Archives: Pvc edge banding article topics

Pvc edge banding article topics

Several alternatives to PVC (polyvinyl chloride) edge banding exist, offering different material options with their own set of characteristics. The choice of edge banding material often depends on factors such as environmental considerations, aesthetic preferences, and specific project requirements. Here are some common alternatives to PVC edge banding: ABS (Acrylonitrile Butadiene Styrene): ABS is a […]

The thickness of edging material that can be used on an edge bander, or edge banding machine, can vary depending on the specific machine’s design and capabilities. Most edge banders are designed to handle a range of edging material thicknesses, but there are limitations based on the machine’s feed mechanisms, pressure rollers, and other factors. […]

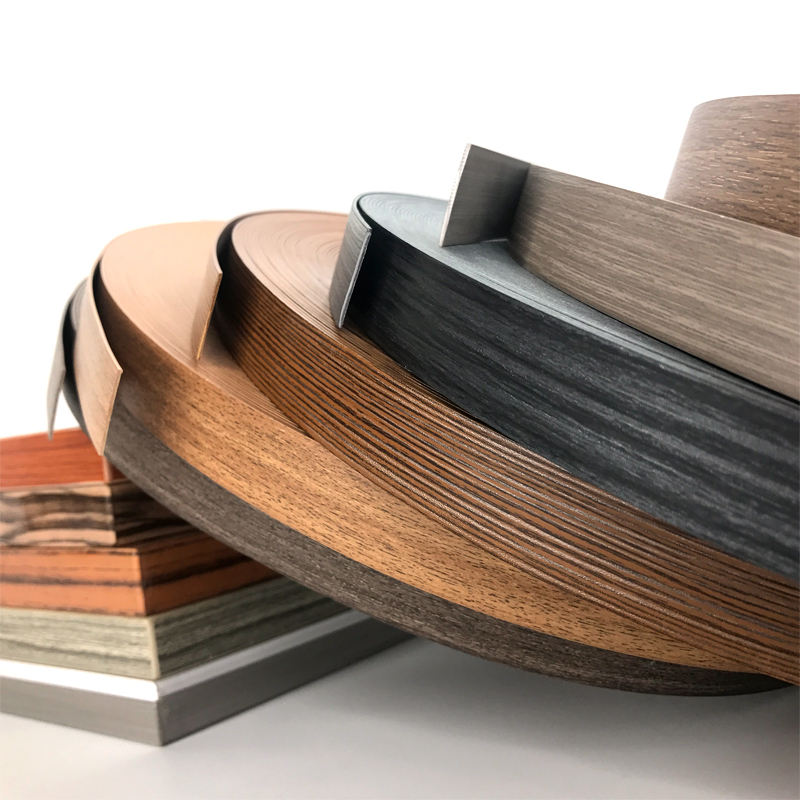

The standard size of edge banding can vary depending on the type of edge banding material and the manufacturer. However, the most common standard sizes for edge banding are typically as follows: Width: Edge banding is available in various widths, but the most common widths are between 15mm to 45mm (approximately 5/8 inch to 1 […]

The “best” edge banding material depends on your specific project requirements, priorities, and budget. Different edge banding materials offer distinct advantages and may be more suitable for particular applications. Here’s a summary of some common edge banding materials and their strengths: PVC (Polyvinyl Chloride) Edge Banding: Advantages: PVC edge banding is known for its durability, […]

The temperature at which pre-glued edge banding should be applied depends on the specific adhesive used in the edge banding and the manufacturer’s recommendations. Pre-glued edge banding typically comes with a heat-activated adhesive, and it requires the right level of heat to ensure a strong and secure bond. Here are some general guidelines for applying […]

Edge banding materials like wood, veneer, and some types of PVC can be stained to match the color and appearance of the substrate or to achieve a desired finish. However, not all edge banding materials are suitable for staining, and the process may require some preparation and techniques to achieve the desired results. Here’s a […]

The temperature for applying PVC edge banding typically ranges between 180 to 220 degrees Celsius (356 to 428 degrees Fahrenheit). This temperature range is crucial for activating the heat-sensitive adhesive on the back of the PVC edge banding, allowing it to bond securely to the substrate (such as plywood, MDF, or particleboard). Here are the […]

Covering the edges of particleboard is commonly done to protect them, provide a finished appearance, and improve durability. You can achieve this using several methods, including edge banding, solid wood, veneer, or various decorative materials. Here’s how to cover the edges of particleboard: 1. PVC Edge Banding: PVC edge banding is a popular choice for […]

Particleboard, often used as a cost-effective substrate in furniture and cabinetry, can be covered or finished in various ways to enhance its appearance and durability. Here are several options for covering particleboard: Laminate or Melamine: Laminate or melamine sheets are a popular choice for covering particleboard. These pre-finished materials come in a wide range of […]