The “best” edge banding material depends on your specific project requirements, priorities, and budget. Different edge banding materials offer distinct advantages and may be more suitable for particular applications. Here’s a summary of some common edge banding materials and their strengths:

- PVC (Polyvinyl Chloride) Edge Banding:

- Advantages: PVC edge banding is known for its durability, resistance to moisture and chemicals, ease of maintenance, and versatility in terms of color and finish options. It’s cost-effective and widely used in various applications.

- Ideal For: Kitchens, bathrooms, commercial furniture, cabinets, and applications where durability and moisture resistance are crucial.

- ABS (Acrylonitrile Butadiene Styrene) Edge Banding:

- Advantages: ABS edge banding offers excellent durability, impact resistance, and moisture resistance. It is also easy to maintain and comes in various colors and finishes.

- Ideal For: High-traffic areas, heavy-duty applications, commercial furniture, and projects where durability is a top priority.

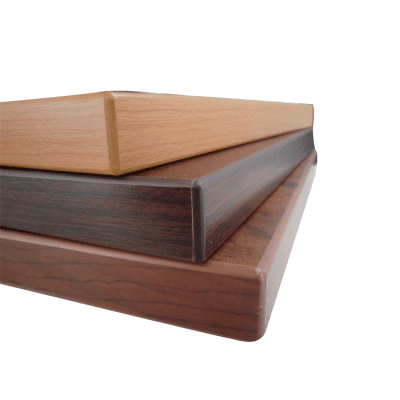

- Wood Edge Banding:

- Advantages: Wood edge banding provides a natural wood appearance and can be stained or finished to match the substrate. It’s ideal for projects where the look and feel of real wood are desired.

- Ideal For: High-end furniture, cabinetry, and applications where aesthetics and authenticity are key.

- Veneer Edge Banding:

- Advantages: Veneer edge banding offers the beauty of real wood with the option to choose from various wood species and grain patterns. It can be stained and finished for a customized appearance.

- Ideal For: High-quality woodworking projects where the warmth and authenticity of wood are essential.

- Melamine Edge Banding:

- Advantages: Melamine edge banding complements melamine-coated or laminated substrates, providing a consistent appearance and excellent protection. It’s available in various colors and textures.

- Ideal For: Melamine-based cabinets, furniture, and shelving.

- Metal Edge Banding:

- Advantages: Metal edge banding offers a modern and industrial look. It provides exceptional durability and protection against impact and wear.

- Ideal For: Contemporary furniture, commercial applications, and projects where a metallic finish is desired.

- Glass Edge Banding:

- Advantages: Glass edge banding creates a unique and translucent finish, often used for modern and decorative applications.

- Ideal For: Contemporary furniture, decorative elements, and projects where a glass-like appearance is desired.

Here are some key factors to consider when determining the best edge banding for your project:

- Durability:

- If durability is a primary consideration, ABS edge banding is known for its toughness and impact resistance. It can withstand daily wear and tear in high-traffic areas.

- Moisture Resistance:

- Consider the environment where the project will be located. For areas prone to moisture, such as kitchens and bathrooms, materials like ABS or PVC, which are resistant to water, may be suitable.

- Aesthetics:

- Choose edge banding that complements the overall design and aesthetic of your project. Wood veneer edge banding provides a natural and authentic wood appearance, while PVC and ABS offer a wide range of colors and patterns for modern designs.

- Ease of Maintenance:

- Consider the ease of cleaning and maintenance. ABS and PVC edge banding are often easier to clean and are resistant to stains, making them suitable for applications in kitchens and other areas with frequent spills.

- Versatility:

- If you need a versatile material that can mimic the look of various materials, PVC and ABS edge banding come in a variety of colors and patterns. Wood veneer edge banding offers versatility in terms of wood species and stains.

- Budget:

- Consider your budget constraints. PVC and ABS edge banding are generally more cost-effective than real wood veneer. Melamine edge banding is another budget-friendly option.

- Matching Existing Woodwork:

- If your project involves matching existing woodwork or furniture, wood veneer edge banding may be the best choice for achieving a seamless match in terms of species and grain.

- Environmental Considerations:

- For those with environmental considerations, some wood veneer and edge banding products are made from sustainable or FSC-certified wood sources.

- Application Method:

- Consider the application method that suits your skills and tools. Some edge banding materials come with pre-glued backing for easier installation, while others may require heat activation.

- Thickness:

- Different edge banding materials come in various thicknesses. Choose a thickness that complements the overall design and profile of your project.

Ultimately, the best edge banding for your project will depend on a combination of these factors. It’s essential to thoroughly evaluate your project requirements, consider the specific characteristics of each edge banding material, and choose the one that best aligns with your needs and preferences.