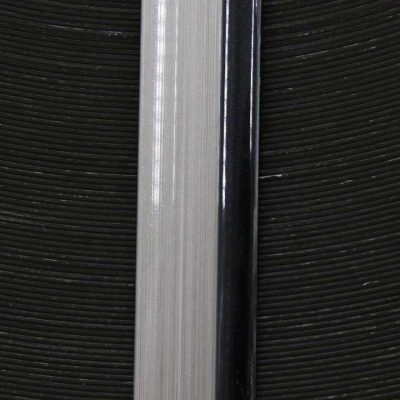

Acrylic edge banding, also known as PMMA (Polymethyl Methacrylate) edge banding, is a type of edge banding material used in furniture and cabinetry to cover and protect the exposed edges of substrates like particleboard or MDF. Like any material, acrylic edge banding has its own set of advantages and disadvantages.

Advantages of Acrylic Edge Banding:

- Aesthetic Appeal:

- Advantage: Acrylic edge banding provides a high-gloss and visually appealing finish. It adds a modern and sleek look to furniture and cabinetry.

- Color Variety:

- Advantage: Acrylic edge banding is available in a wide range of colors, making it easy to match or contrast with the surface material. The color consistency is typically high.

- UV Resistance:

- Advantage: Acrylic is resistant to ultraviolet (UV) light, meaning that it is less likely to fade or yellow when exposed to sunlight over time.

- High Durability:

- Advantage: Acrylic edge banding is durable and resistant to scratches and impact. It provides a protective layer to the edges of the substrate, enhancing overall durability.

- Smooth Surface:

- Advantage: Acrylic edge banding offers a smooth and non-porous surface, which is easy to clean and maintain. This can be particularly advantageous in applications where cleanliness is important.

- Chemical Resistance:

- Advantage: Acrylic is resistant to many chemicals, which contributes to its durability and suitability for various applications.

- Thermoforming Capabilities:

- Advantage: Acrylic has thermoforming capabilities, allowing it to be molded and shaped under heat. This flexibility can be useful for certain design applications.

- Modern Aesthetics:

- Advantage: Acrylic edge banding is often chosen for modern and contemporary designs, providing a high-end and polished appearance.

Disadvantages of Acrylic Edge Banding:

- Cost:

- Disadvantage: Acrylic edge banding can be more expensive compared to some other edge banding materials. The cost may be a consideration for budget-conscious projects.

- Brittleness:

- Disadvantage: Acrylic can be relatively brittle, and in certain applications, it may be more prone to chipping or cracking compared to more flexible materials like PVC.

- Application Challenges:

- Disadvantage: Acrylic edge banding may require careful handling during application due to its tendency to be less flexible. It may not be as forgiving as more pliable edge banding materials.

- Limited Flexibility:

- Disadvantage: Acrylic is not as flexible as some other materials, making it less suitable for applications that involve curved or contoured edges.

- Weight:

- Disadvantage: Acrylic can be heavier than some alternative edge banding materials, potentially adding weight to the finished product.

- Environmental Impact:

- Disadvantage: While acrylic itself is a recyclable material, the production processes and environmental impact of acrylic can be a concern for those seeking more sustainable options.

- Disadvantage: While acrylic itself is a recyclable material, the production processes and environmental impact of acrylic can be a concern for those seeking more sustainable options.

In summary, acrylic edge banding offers a visually striking and durable solution for modern furniture and cabinetry. However, its higher cost, potential brittleness, and limited flexibility may be considerations depending on the specific requirements of a project. It’s essential to weigh these factors and choose the edge banding material that aligns best with the design, functionality, and budgetary constraints of the project.