EVA (Ethylene Vinyl Acetate) and PUR (Polyurethane Reactive) are two different types of adhesives used in the production of edgebanding, which is applied to the edges of panels, such as those used in furniture manufacturing. Here are the key differences between EVA and PUR edgebanding glue: EVA (Ethylene Vinyl Acetate) Edgebanding Glue: Application: EVA glue […]

Author Archives: Zhi Shang edge banding manufacturer

The quality of acrylic edge banding strips can vary depending on several factors, including the manufacturer, the production process, and the specific product’s features. When evaluating the quality of acrylic edge banding strips, consider the following key factors: Material Quality: High-quality acrylic edge banding is typically made from premium acrylic material. Look for products that […]

AZEK is a brand that offers a variety of building materials, including cellular PVC (Polyvinyl Chloride) products. PVC glue, in the context of construction and woodworking, typically refers to adhesive products specifically designed for bonding PVC materials. While AZEK itself produces PVC-based products, it’s essential to note that the term “AZEK glue” is not a […]

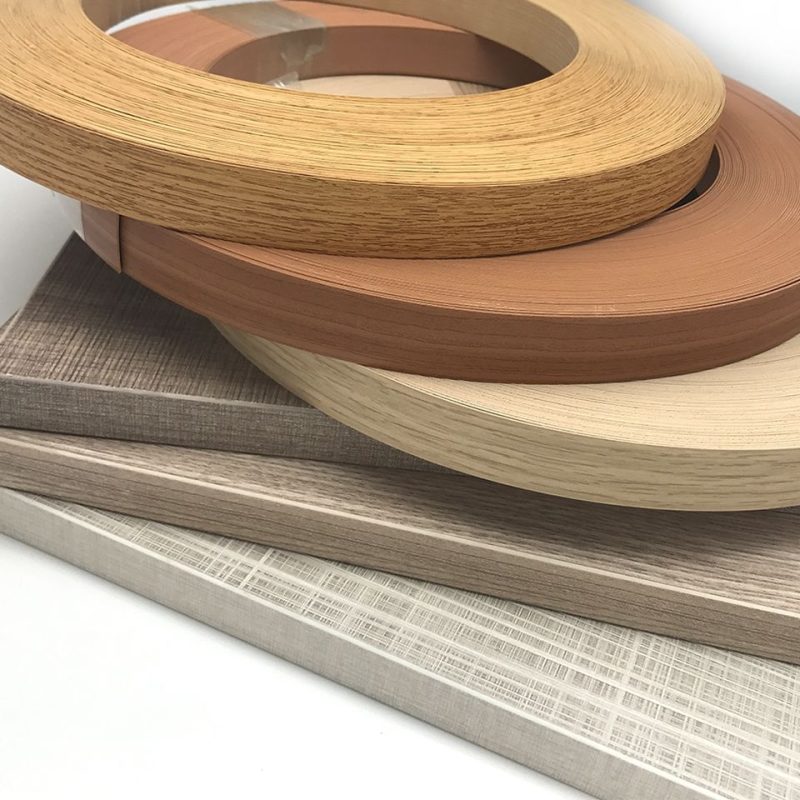

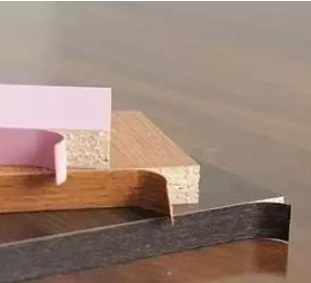

The primary difference between 1mm and 3mm edge banding lies in their thickness or width. Both 1mm and 3mm edge banding serve similar purposes, but they are used in different situations and have distinct characteristics. Here are the key differences: 1mm Edge Banding: Thickness: As the name suggests, 1mm edge banding is approximately 1mm in […]

To glue PVC edging to plywood, follow these steps for a strong and durable bond: Materials You’ll Need: PVC edge banding Plywood PVC edge banding adhesive (typically a hot melt adhesive) Edge banding trimmer or utility knife Edge banding roller or a block of wood Clothes iron or edge banding machine with a heated applicator […]

Melamine edge banding is a type of edge treatment used to cover the exposed edges of melamine boards or other substrates with a melamine surface. Melamine edge banding is available in various types, including different colors, patterns, and finishes. Here are some common types of melamine edge banding: Solid Color Melamine Edge Banding: This type […]

The temperature at which EVA (Ethylene Vinyl Acetate) polymer decomposes can vary depending on the specific formulation and grade of EVA, as well as other factors such as the presence of additives. However, in general, EVA starts to decompose at elevated temperatures, typically well above its melting point. The melting point of EVA can range […]

EVA (Ethylene Vinyl Acetate) hot melt adhesive, commonly used in woodworking and edge banding applications, typically melts and flows at a temperature range of approximately 150°C to 180°C (302°F to 356°F). This temperature range allows EVA hot melt adhesive to become molten and ready for application. When using EVA hot melt adhesive, it’s important to […]

The temperature at which you should glue edge banding depends on the type of adhesive you are using. The most common adhesive for edge banding is hot melt adhesive (hot glue), and it is typically applied within a specific temperature range. Here are general temperature guidelines for gluing edge banding with hot melt adhesive: Temperature […]

The choice of adhesive for PVC edge banding is critical to achieving a strong and long-lasting bond. The “best” adhesive can vary depending on factors such as the application method, environmental conditions, and personal preferences. However, there are several types of adhesives commonly used for bonding PVC edge banding to substrates like plywood, MDF, or […]