Finishing acrylic edges involves processes to achieve a smooth, polished, and aesthetically pleasing look on the cut edges of acrylic sheets. Acrylic, also known as plexiglass or PMMA (Polymethyl Methacrylate), is a transparent plastic material commonly used in various applications. Here’s a guide on how to finish acrylic edges: Tools and Materials Needed: Fine […]

Author Archives: Zhi Shang edge banding manufacturer

The thickness of edging material that can be used on an edge bander, or edge banding machine, can vary depending on the specific machine’s design and capabilities. Most edge banders are designed to handle a range of edging material thicknesses, but there are limitations based on the machine’s feed mechanisms, pressure rollers, and other factors. […]

“Laminate with ABS edging” typically refers to a type of furniture or cabinetry construction where a laminate finish is applied to a core material, such as particleboard or MDF (Medium-Density Fiberboard), and then ABS (Acrylonitrile Butadiene Styrene) edge banding is used to protect and seal the exposed edges of the laminate. Here’s a breakdown of […]

Reheating edge banding is generally not recommended. Edge banding adhesive, whether it’s hot melt adhesive or another type, is designed to create a strong and lasting bond when initially applied and activated. Once the adhesive has fully set or cured, reheating the edge banding is unlikely to achieve the same level of bonding strength, and […]

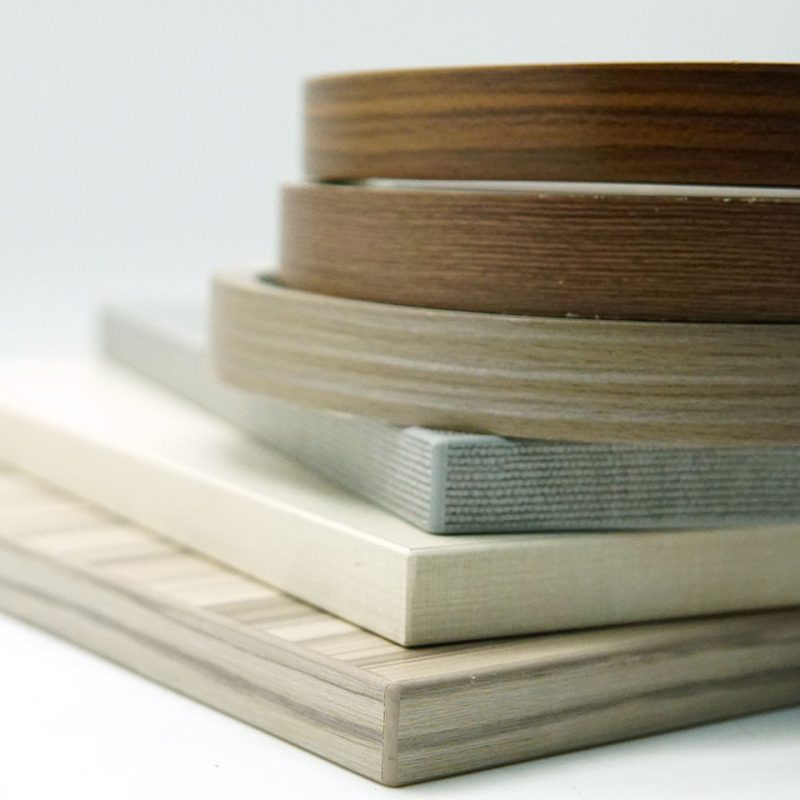

The standard size of edge banding can vary depending on the type of edge banding material and the manufacturer. However, the most common standard sizes for edge banding are typically as follows: Width: Edge banding is available in various widths, but the most common widths are between 15mm to 45mm (approximately 5/8 inch to 1 […]

Yes, you can put edge banding on MDF (Medium-Density Fiberboard). Edge banding is commonly used on MDF to finish and protect the exposed edges of the material. The process of applying edge banding to MDF is similar to applying it to other engineered wood products like plywood and particleboard. Here are the steps to apply […]

Edge banding is used most often in various woodworking and furniture-making applications to finish and protect the exposed edges of materials like plywood, particleboard, MDF (Medium-Density Fiberboard), and even solid wood. It is a common practice in both residential and commercial settings. Some of the primary areas where edge banding is used most often include: […]

Yes, you can use a regular household iron for edge banding, but it’s important to follow some precautions and take certain considerations into account to ensure a successful and safe application. Edge banding with a regular iron is a cost-effective alternative to specialized edge banding irons or machines. Here’s how to do it: Materials You’ll […]

Yes, edge banding can be used on MDF (Medium-Density Fiberboard). Edge banding is a common and effective way to finish and protect the exposed edges of MDF, just as it is used on other engineered wood products like plywood and particleboard. Here are the steps to apply edge banding to MDF: Materials You’ll Need: Edge […]

Waterproofing plywood edges is important, especially in applications where the plywood is exposed to moisture or weather conditions. The edges of plywood are particularly vulnerable to water penetration, and sealing them properly helps prevent swelling, delamination, and damage over time. Here are steps to waterproof plywood edges: Materials and Tools Needed: Waterproofing Sealant: Choose a […]