Gluing edge banding to particle board is a common practice in woodworking and cabinetmaking to create a clean, finished edge and protect the particle board from moisture. Here are the steps to glue edge banding to particle board: Materials You’ll Need: Edge Banding: Choose the type of edge banding material you prefer, such as PVC, […]

Author Archives: Zhi Shang edge banding manufacturer

A hair dryer can be used to apply heat to edge banding, but it may not be the most efficient or precise method, especially when compared to tools designed for edge banding like edge banding irons or specialized edge banding machines. However, in a pinch or for small projects, a hair dryer can serve as […]

The best adhesive for attaching melamine edge banding to melamine surfaces is typically contact cement or a specialized edge banding adhesive designed for use with melamine. These adhesives are chosen for their ability to bond melamine effectively and provide a durable, long-lasting connection. Here’s a closer look at these adhesive options: Contact Cement: Advantages: Contact […]

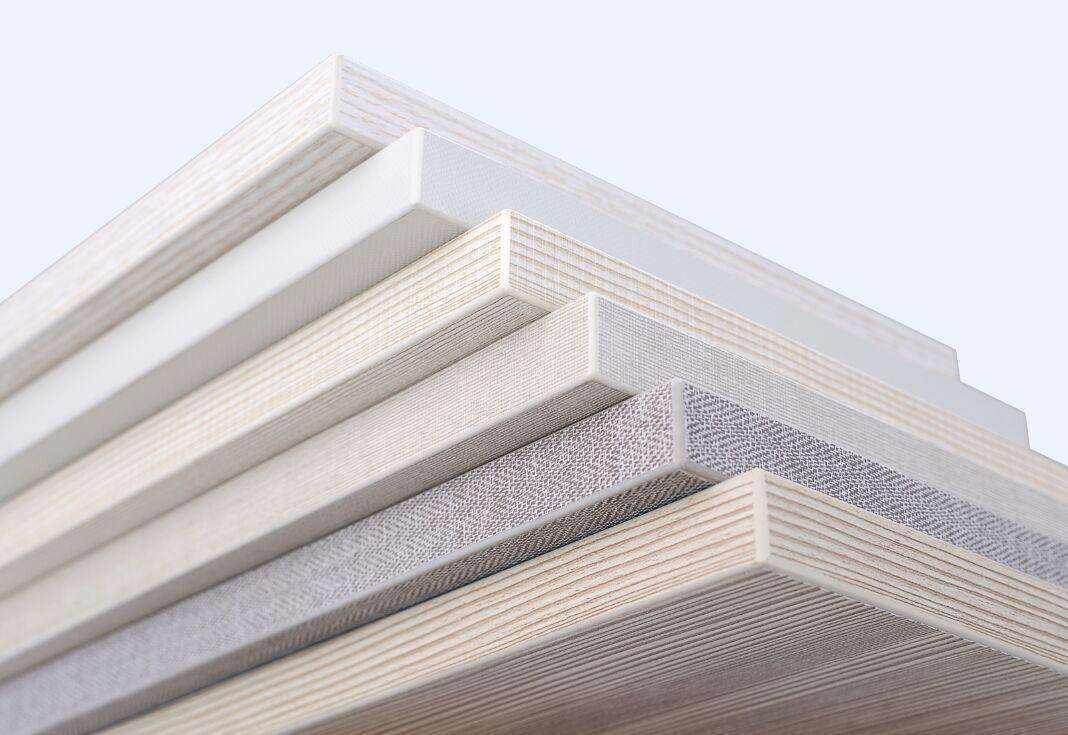

Sealing plywood edges is important to protect them from moisture infiltration, which can lead to swelling, warping, and other forms of damage. There are several effective methods and products you can use to seal plywood edges: Wood Glue: Wood glue, such as standard PVA (Polyvinyl Acetate) glue, can be used to seal plywood edges. Simply […]

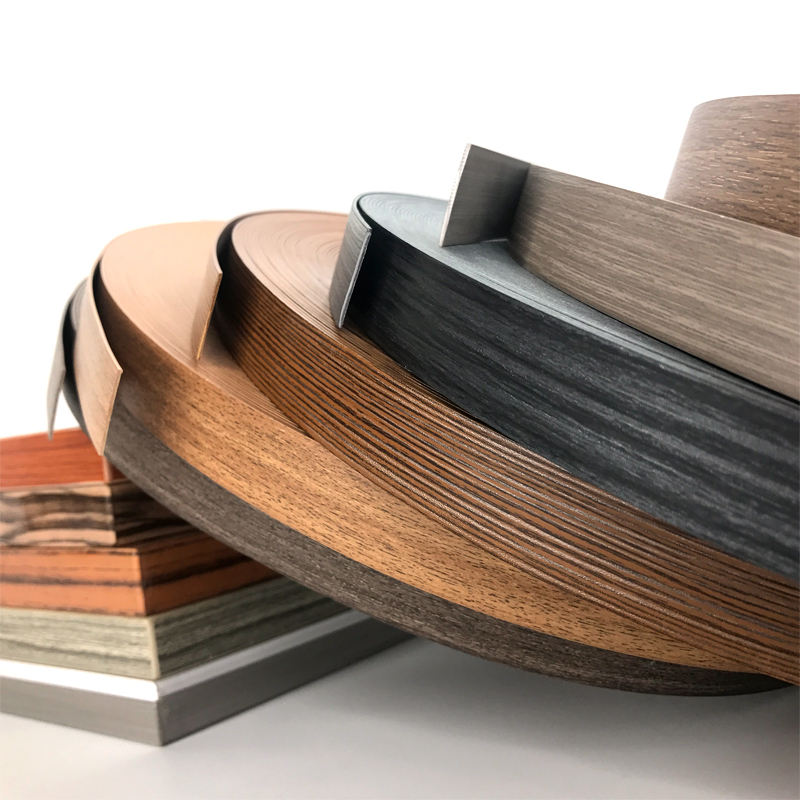

The “best” edge banding material depends on your specific project requirements, priorities, and budget. Different edge banding materials offer distinct advantages and may be more suitable for particular applications. Here’s a summary of some common edge banding materials and their strengths: PVC (Polyvinyl Chloride) Edge Banding: Advantages: PVC edge banding is known for its durability, […]

The temperature at which pre-glued edge banding should be applied depends on the specific adhesive used in the edge banding and the manufacturer’s recommendations. Pre-glued edge banding typically comes with a heat-activated adhesive, and it requires the right level of heat to ensure a strong and secure bond. Here are some general guidelines for applying […]

Melamine, when exposed to water or moisture, can experience several adverse effects, as it is not naturally moisture-resistant. Here’s what happens to melamine when it gets wet: Swelling: Melamine is a porous material, and when it absorbs moisture, it can swell. This swelling can lead to changes in the dimensions of the melamine surface, causing […]

Edge banding materials like wood, veneer, and some types of PVC can be stained to match the color and appearance of the substrate or to achieve a desired finish. However, not all edge banding materials are suitable for staining, and the process may require some preparation and techniques to achieve the desired results. Here’s a […]

The choice between ABS (Acrylonitrile Butadiene Styrene) and veneer edging depends on various factors, including the specific requirements of your project, your design preferences, and the desired characteristics of the edge banding material. Both ABS and veneer edging have their advantages and considerations, so it’s essential to evaluate the following aspects to determine which may […]

The temperature for applying PVC edge banding typically ranges between 180 to 220 degrees Celsius (356 to 428 degrees Fahrenheit). This temperature range is crucial for activating the heat-sensitive adhesive on the back of the PVC edge banding, allowing it to bond securely to the substrate (such as plywood, MDF, or particleboard). Here are the […]