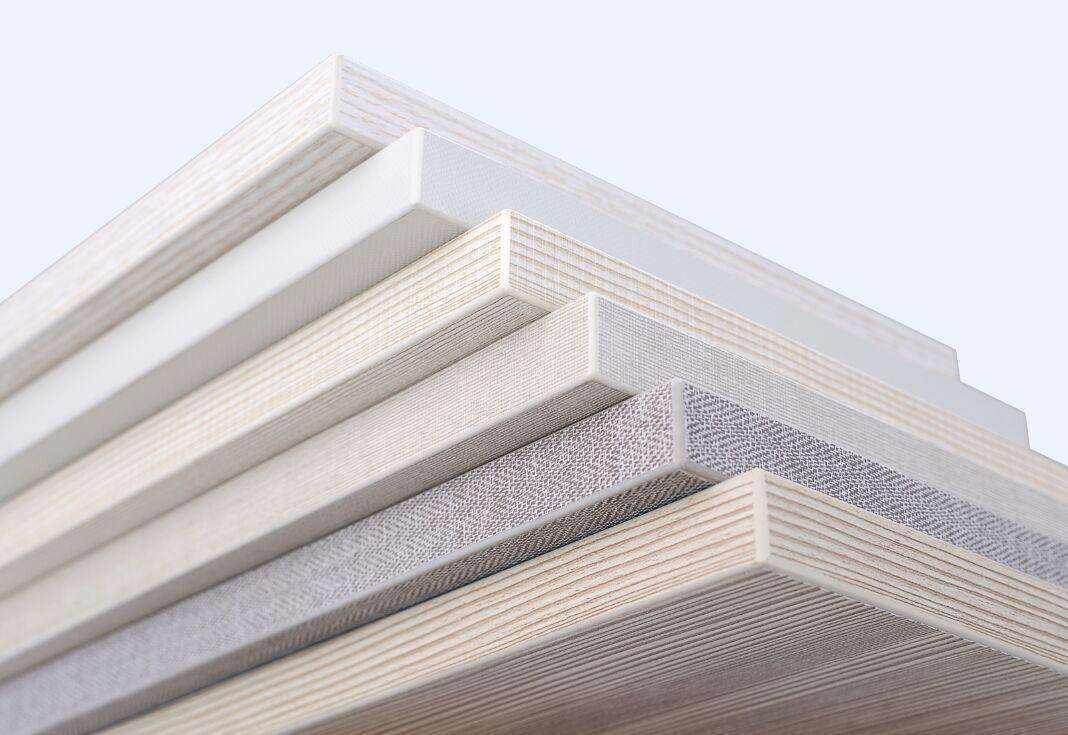

Installing melamine edge banding involves applying a thin strip of melamine material to the exposed edges of a substrate, typically made of particleboard, MDF (medium-density fiberboard), or plywood. The edge banding serves to protect the edges and create a finished, cohesive look. Here’s a step-by-step guide on how to install melamine edge banding: Tools and […]

Category Archives: Edge Banding article topics

Edge Banding article topics

Pre-glued edge banding refers to a type of edge banding material that comes with adhesive already applied to one side. This adhesive is activated by heat, typically using an iron or an edge banding machine, facilitating the bonding process during application. The pre-glued edge banding eliminates the need for a separate adhesive application step, making […]

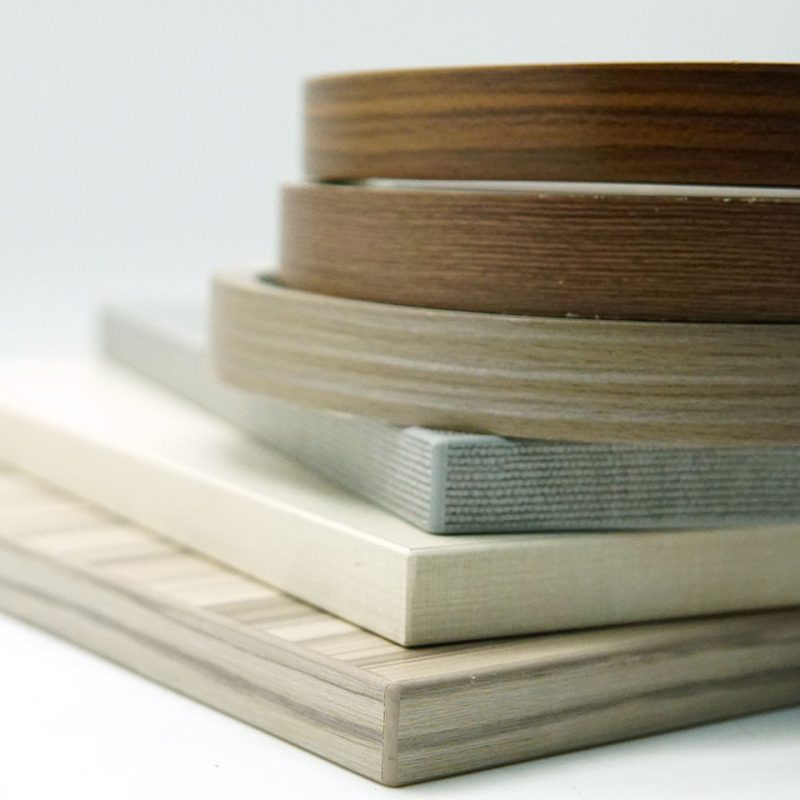

Several alternatives to PVC (polyvinyl chloride) edge banding exist, offering different material options with their own set of characteristics. The choice of edge banding material often depends on factors such as environmental considerations, aesthetic preferences, and specific project requirements. Here are some common alternatives to PVC edge banding: ABS (Acrylonitrile Butadiene Styrene): ABS is a […]

Removing melamine edge banding can be done with careful consideration to avoid damaging the underlying material. Here’s a general guide on how to remove melamine edge banding: Tools and Materials Needed: Utility Knife or Razor Blade: A sharp utility knife or razor blade will be essential for cutting and scoring the edge banding. Heat Gun: […]

Reheating edge banding is generally not recommended. Edge banding adhesive, whether it’s hot melt adhesive or another type, is designed to create a strong and lasting bond when initially applied and activated. Once the adhesive has fully set or cured, reheating the edge banding is unlikely to achieve the same level of bonding strength, and […]

Yes, you can put edge banding on MDF (Medium-Density Fiberboard). Edge banding is commonly used on MDF to finish and protect the exposed edges of the material. The process of applying edge banding to MDF is similar to applying it to other engineered wood products like plywood and particleboard. Here are the steps to apply […]

Edge banding is used most often in various woodworking and furniture-making applications to finish and protect the exposed edges of materials like plywood, particleboard, MDF (Medium-Density Fiberboard), and even solid wood. It is a common practice in both residential and commercial settings. Some of the primary areas where edge banding is used most often include: […]

Yes, you can use a regular household iron for edge banding, but it’s important to follow some precautions and take certain considerations into account to ensure a successful and safe application. Edge banding with a regular iron is a cost-effective alternative to specialized edge banding irons or machines. Here’s how to do it: Materials You’ll […]

Gluing edge banding to particle board is a common practice in woodworking and cabinetmaking to create a clean, finished edge and protect the particle board from moisture. Here are the steps to glue edge banding to particle board: Materials You’ll Need: Edge Banding: Choose the type of edge banding material you prefer, such as PVC, […]

A hair dryer can be used to apply heat to edge banding, but it may not be the most efficient or precise method, especially when compared to tools designed for edge banding like edge banding irons or specialized edge banding machines. However, in a pinch or for small projects, a hair dryer can serve as […]